A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as zeroing, shaving, facing, cutting, tapping, drilling/boring, and turning down with tools that are applied to the workpiece to create an object with symmetry about that axis.

Stock Types

The difference between hex and thunderhex is the roundness of the edge. Hex has sharp pointy edges while thunderhex is more flat and rounded on its edges. We primarily use thunderhex because we use thunderhex bearings. | |

We have ½” and ⅜” stock. This means the outside diameter of the part is one of these widths, respectively. On round stock, you can measure this diameter from anywhere, but on hex and thunderhex stock, this diameter can be seen by measuring from opposite flat edges. | |

...

This diagram shows each of the dimensions required to read and effectively use a part drawing. Important:

|

Safety Precautions

- Never use gloves while operating the lathe because it may get caught.

- Hair tied back, safety glasses, make sure nothing loose is dangling over the lathe (e.g. hoodie strings, baggy clothes, jewelry).

- Keep hands and body a safe distance from the cutting line and spinning parts on the lathe.

- Be cautious of heat: The metal stock gets very hot quickly.

- Always remove the tightening key from the chuck before starting the machine.

- Ensure the lathe spins towards you when turned on.

Machine Setup and Operation

...

- The process for facing is the same as shaving, but the increments are much smaller: .005-.01”.

- Facing is used for the last few cuts of a part to achieve the smoothest edge. The smaller the increments, the better the cuts.

Tapping

Preparation

|

Steps

- Place your part at least 70% in the lathe.

- Turn the speed setting to the lowest. This is essential, as going too fast will likely break or weaken the tap as they are very fragile.

- Turn the black knob left and push the entire chuck mechanism gently towards your part until the tip of the tap is just against your part.

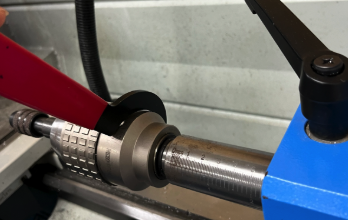

- Slowly turn the wheel (pictured) clockwise until the chuck mechanism starts moving into the part on its own.

- Once you’ve tapped halfway to the tap length, turn the black knob back to the center.

- Turn the black knob to the right to take the tap out of the part (this is the ONLY time the lathe should ever spin away from you).

- Clean the tap and part with air.

- Repeat this process, this time going all the way to your desired length.

- Repeat this once again to ensure clear threads.

...